Good electrical insulation performance and high dielectric strength.

High borosilicate glass (also known as

hard glass) is also known as "borosilicate glass 3.3" due to its linear

thermal expansion coefficient of (3.3 ± 0.1) X10-6/K. It is a special

glass material with low expansion rate, high temperature resistance,

high strength, high hardness, high light transmittance, and high

chemical stability. Due to its excellent performance, it is widely used

in industries such as solar energy, chemical industry, pharmaceutical

packaging, electric light sources, and craft accessories. Its excellent

performance has been widely recognized by various sectors of the world,

especially in the field of solar energy, which is more widely used.

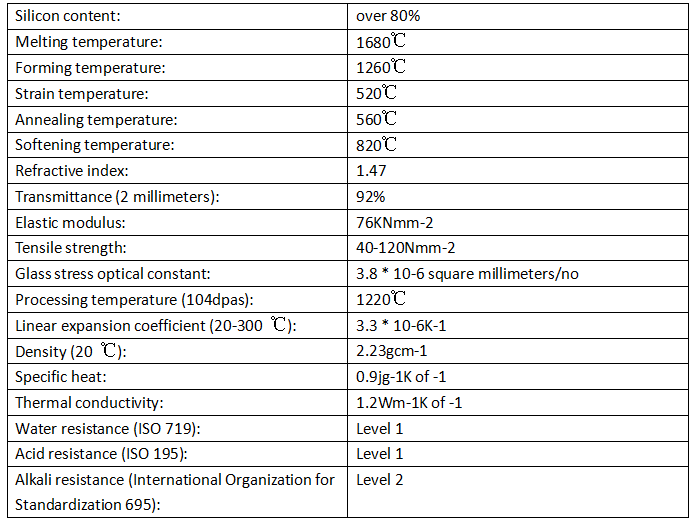

Physical and chemical properties

The

linear expansion coefficient of high borosilicate glass is

3.3±0.1X10-6/K, which is a type of glass composed mainly of sodium oxide

(Na2O), boron oxide (B202), and silicon dioxide (SIO2). This type of

glass has a high content of boron and silicon, with boron content

ranging from 12.5% to 13.5% and silicon content ranging from 78% to 80%.

Therefore, it is called high boron silicon glass. PYREX glass belongs

to borosilicate glass. It is acid resistant, alkali resistant, and water

resistant, with superior corrosion resistance and good thermal

stability, chemical stability, and electrical performance. Therefore, it

has characteristics such as resistance to chemical erosion, thermal

shock, good mechanical properties, and high temperature resistance.

Borosilicate glass begins to soften at approximately 821℃ (1510℉).

Borosilicate glass is less dense than ordinary glass.

Although

borosilicate glass has better thermal vibration resistance than other

types of glass, it can still break due to rapid or uneven temperature

changes. When broken, the cracks in borosilicate glass are often larger

than crushed.

In terms of

optical performance, borosilicate glass has low dispersion (about 65

Abbe coefficient) and relatively low refractive index (the entire

visible light range is 1.51-1.54)