sales@qimglass.com

+86 177 2018 9205

Expansion coefficient

10.4 x 10-6/K (room temperature~300 ℃)

Refractive index

ND=1.5755

Softening point

526 ℃

Annealing point

470 ℃

Strengthening process

Strengthened in tempering furnace, soaked by potassium nitrate.

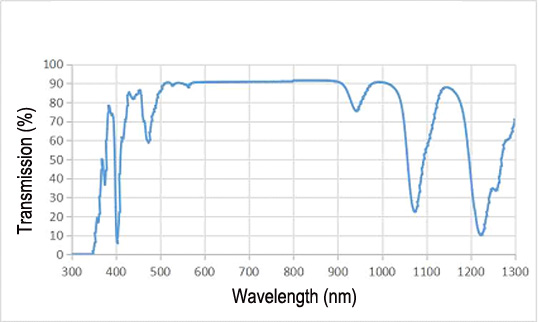

Spectrum